Titanium Products

About Titanium Products

Laube Titanium has been building relationships in the metals industry since 1948. We’re a leading supplier of quality titanium to manufacturers in industries throughout the United States. We’re known for our superior products and services, on-time delivery, and competitive prices. Whatever your needs, we supply premium titanium bars, sheets, plates, and tubes to meet them.

TITANIUM PRODUCTS

Delivered on time and within budget

Titanium Bars

Titanium Tubes

Titanium Sheets & Plates

Engineered Titanium

Services Offered

Custom-processed titanium sheets, plates, bars, and tubes to your specifications

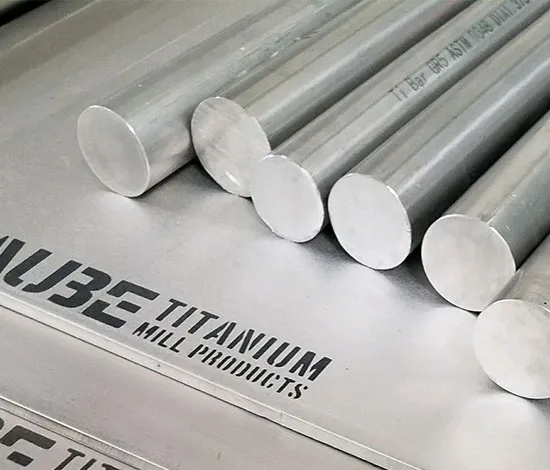

Titanium Bars

PRECISION-ENGINEERED, ULTRASONIC-TESTED TITANIUM BARS IN VARIOUS GRADES AND SIZES

Safety and functionality guaranteed

We offer domestic and imported titanium bars in various grades and sizes. Our materials are Precision-engineered to ensure their safety and functionality. Sizes range from .250″ – 14.00″ in diameter and between 8′-14′ in length.

We also provide custom-cut sizes for special projects and easy shipping. Please use our Weight Calculator to determine the total weight per piece of your order, based on your custom dimensions.

Titanium bars are commonly supplied to the following standards:

- ASTM B348, AMS-4928

- AMS-6931, AMS-T-9047 (6AL-4V Grade 5)

- MIL-T-9047 (6AL-4V Grade 5), AMS-4967

- ASTM-F67 (CP Grades 1-4), ASTM F-1472 (6AL-4V Grade 5)

- ASTM-F-136 (6AL-4V ELI)

Our titanium bars currently serve several industries, which include (but are not limited to):

- Racing

- Weapon accessories manufacturers

- Industrial fasteners

- Medical instrument manufacturers

- Military and aerospace applications

Titanium bars can be composed of pure titanium (commercially pure grades 1-4) or a mixture of pure titanium and other alloys such as aluminum or vanadium (Grade 5 or Grade 23). Titanium rods can be used for a number of different applications for several different industries. The most popular ones are used in aerospace and medical applications.

Titanium Tubes

TOUGH WELDED AND SEAMLESS TITANIUM TUBING PERFECTED FOR YOUR INDUSTRY

Corrosion-resistant tubes made with precision

We provide seamless and welded titanium tubing in CP Grade 2 and titanium alloy Grade 9 (3AL-2.5V). The sizes range from .375″ – 2.00″ OD with wall thickness from .016″ – .109″ and lengths from 10′-20′.

We also offer custom-cut sizes for special projects and easy shipping. Please use our Weight Calculator to determine the total and weight per piece of your order, based on your custom dimensions.

Titanium tubes are commonly supplied to the following standards:

- ASTM- B338, AMS-4942

- AMS 4943, AMS 4944, AMS 4945

Our titanium tubes are currently being used in the following industrial applications:

- Pulp & Paper

- Recreation

- Marine

- Chemical

Welded titanium tubes are used to produce process equipment such as heat exchangers, tanks, process vessels, and valves that are used in the chemical and petrochemical industries primarily for corrosion resistance. Because of its high resistance to corrosion by seawater, titanium is used in propeller shafts, rigging, heat exchangers, heater-chillers for salt water aquariums, fishing line and leader, and divers’ knives. Titanium is also used as a component in housings and ocean-deployed surveillance and monitoring devices for science and the military.

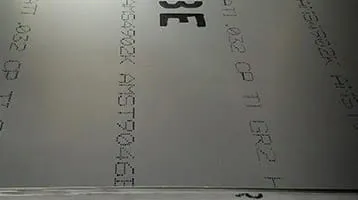

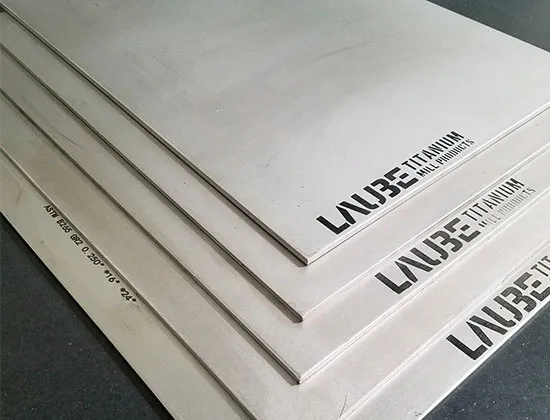

Titanium Sheets & Titanium Plates

STRONG, DURABLE TITANIUM SHEETS AND PLATES FOR ANY APPLICATION

Made to exceed the standards

We offer domestic and imported titanium sheets and plates in various grades and sizes. The sizes range from .012″ – 3.00″ in thickness, 36″ – 48″ in width, and between 96″-120″ in length.

We also provide custom-cut sizes for special projects and easy shipping. Please use our Weight Calculator to determine the total and weight per piece of your order, based on your custom dimensions.

Titanium sheets and plates are commonly supplied to the following standards:

- ASTM-B-265, AMS-4900

- AMS-4901, AMS-4902

- AMS-4911, AMS-T-9046 (6AL-4V Gr.5)

- MIL-T-9046 (6AL-4V Gr.5)

- ASTM-F67, ASTM F-1472 and ASTM F-136

Our titanium sheets and plates currently serve several industries, which include (but are not limited to):

- Aerospace manufacturers

- Industrial application manufacturers (recreational sports, survival weapons, fasteners)

- Medical instrument manufacturers

- Electronic manufacturers

ASTM grades 1 to 4 are commercially pure (unalloyed). They vary in tensile strength as a function of oxygen content. In addition to the ASTM specifications, titanium alloys are also produced to meet aerospace and military specifications (SAE-AMS, MIL-T), ISO standards, and country-specific specifications, as well as proprietary end-user specifications for aerospace, military, medical, and industrial applications.

Engineered Titanium Components

QUALITY METAL COMPONENTS CUSTOM-MADE TO YOUR SPECIFICATIONS

At Laube Titanium we are focused on always being your preferred supplier for the highest quality titanium mill products. Realizing that some customers are interested in outsourcing certain component parts of their overall assemblies, Laube Titanium can satisfy those requirements by offering Custom Engineered Titanium Components manufactured to exact specifications. Titanium dental discs, titanium firing pins and Titanium Mine Probes are only a few examples of finished parts that Laube Titanium Mill Products can offer.

All customer drawings and specifications are kept confidential. We will be happy to sign non-disclosure agreements upon request.

We look forward to receiving your inquiries.

Weight Calculator

ESTIMATE THE TOTAL WEIGHT OF YOUR TITANIUM ORDER WITH OUR USER-FRIENDLY CALCULATOR

PREMIUM-QUALITY PRODUCTS FROM LAUBE TITANIUM

Preferred by Leading Manufacturers

Call us today (805-388-1050) to get a quick and easy quote, or fill out our contact form below.

Our Location

550 Via Alondra, Camarillo, CA 93012, United States

Quick Contact

Fax: 805-388-3433

Email: lily@laube.com